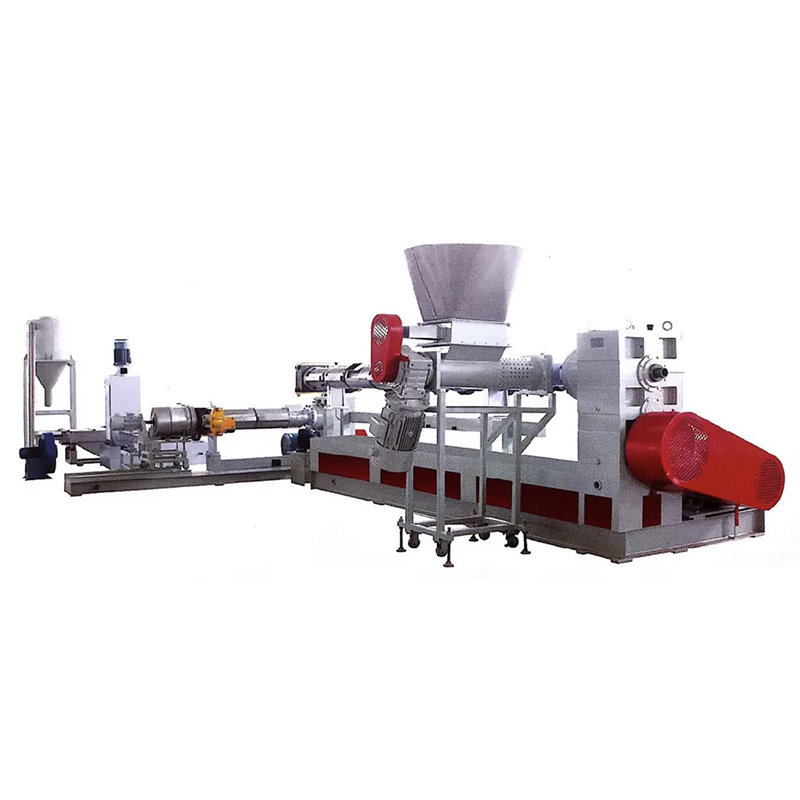

Single screw pelletizing machine

This pelletizing machine has special screw design and different configuration, it is suitable for the recycling of PP, PE, PS, ABS,PC, etc. The gearbox is high torque designed which attains the functions of low noise and stable operation. The surface of the screw and barrel have been special treated so that the screw and barrel are wearable, and they have very high mixing efficiency and the production capacity is high.The extruder has the vacuum vented design which can exhaust the vapor or gas during the production, so that the output are more stable and the pellets are more uniform.

Single Screw Pelletizing Machine Main Technical Parameter

|

Model

|

Screw dia.(mm)

|

L/D

|

Screw speed(rpm)

|

Power of main motor(kw)

|

Output(kg/h)

|

|

JWL45

|

45

|

25-35

|

20-100

|

11-15

|

30-50

|

|

JWL65

|

65

|

25-35

|

20-100

|

30-37

|

60-120

|

|

JWL90

|

90

|

25-35

|

20-90

|

45-55

|

180-200

|

|

JWL120

|

120

|

25-35

|

20-75

|

75-110

|

250-350

|

|

JWL150

|

150

|

25-35

|

20-75

|

110-160

|

350-500

|

|

JWL160

|

160

|

25-35

|

20-70

|

132-185

|

400-550

|

|

JWL180

|

180

|

25-35

|

20-70

|

200-250

|

600-800

|

|

JWL200

|

200

|

25-35

|

20-60

|

250-315

|

800-1100

|

JWL65 Water Ring Single Screw Pelletizing Line

| Equipment operating conditions |

|

| Power conditions | AC380V±10% 50Hz 3P+E |

| Cooling Water | ≤22℃ 0.3~0.4Mpa |

| Material | Suitable for granulation of dry and clean PE recycled materials |

| Capacity | 60-80Kg/h |

| Equipment List |

|

| 1DYSL102 Screw feeder | 1set |

| JWL65/34 Extruder | 1set |

| JHW100A Hydraulic Screen Exchanger | 1set |

| Die head | 1set |

| Water ring cutter | 1set |

| De-watering device | 1set |

| ZS-300 Vibrating screen | 1set |

| DYSLD133 Air Transport Storing Uni | 1set |

| Electric Control System | 1set |

| Technical Parameters | |

| 1DYSL102 Screw Feeder |

|

| Drive Motor | 1.1kw |

| Control model | time relay |

| screw materials | stainless |

JWL65/34 venting single screw extruder

Screw material of 38CrMoAlA, with quenching nitride treatment, hardness more than HV900,integral barrel design ,and vacuum venting system,L/D ration is 34:1.

Ceramic heating rings with cover, all 7zones, total heating power of 21.5Kw, air cooling on barrel,cooling power of 0.18*7=1.26Kw.

High quality of domestic gear box, with super torque, low noise, stable processing. And oil outer recycling cooling system for the gear box.

AC motor ,power of 37Kw, motor connected with belt, with ABB inverter.

Output capacity of 60~80Kg/h, good plasticizing, stable processing, makes sure the material will be distributed uniformly into mold.

The extruder temperature control adopts popular parameter, and mainly adopts SIEMENS or CHIT. The current, the voltage and pressure can be displayed and controlled easily.

| JHW100A Hydraulic Screen Exchanger |

|

| Drive Motor | 1.5kw |

| Pressure range | 0~15Mpa |

| Mesh Board dia. | φ100mm |

| Exchanger heated by electric, and the heating voltage is 220V |

|

| Exchanger board material adopts high quality alloy |

|

| Exchanging methods | hydraulic exchanging |

| Hydraulic station |

|

| Exchanger material | 38CrMoAlA, tempering, nitriding, chromeplate and polishing |

| Heating control zone | 3 zone |

| heating power | 4kw |

| DYMJ300 Die head | |

| The body is made of high quality alloy, reasonable structure and high quality. | |

| DYSQ300 Water ring system |

|

| Cutting power | 1.5kw |

| Material | Aluminum cast material |

| Blade quantity | 3 pieces |

| DYTS300 De-watering device |

|

| Material | The material contact place is made of stainless steel. |

| De-watering power | 4kw |

| Circulating pump | 2.2KW |

| ZS300 Vibration | |

| double layer screen mouth, three outlet | |

| material | stainless steel |

| 0.22kw*2 / Motor power | 0.22kw*2 |

| DYSLD133 Air transport storing unit | |

| 3KW / Feeding air blow power | 3KW |

| Feeding pipe silo volume | 0.75 m3 |

| Material | Stainless steel |

| Electric Control System | |

| 3 phase 380V , A.C. 50HZ | |

| Temperature is controlled by popular meter | |

| Electric part mainly adopts SIEMENS or CHIT | |

| Extruder speed regulation controlled by ABB | |

| feed inverter is from ABB brand | |

| Thermocouple adopts compensation lead avoid the loss of signal during transportation. | |

| Special Tools |

|

| Screw dismount tool | 1set |

| Spare part | |

| Single screw heater | 2 pcs |

| V belt | 1 sets |

| Exchanger heater | 1 set |

| Seal copper ring | 1 set for each |

| Cooling fan | 1 pcs |

| Temperature control meter | 2 pcs |

| Thermocouple | 5 pcs |

| Contactor | 2 pcs |

| Relay | 5 pcs |

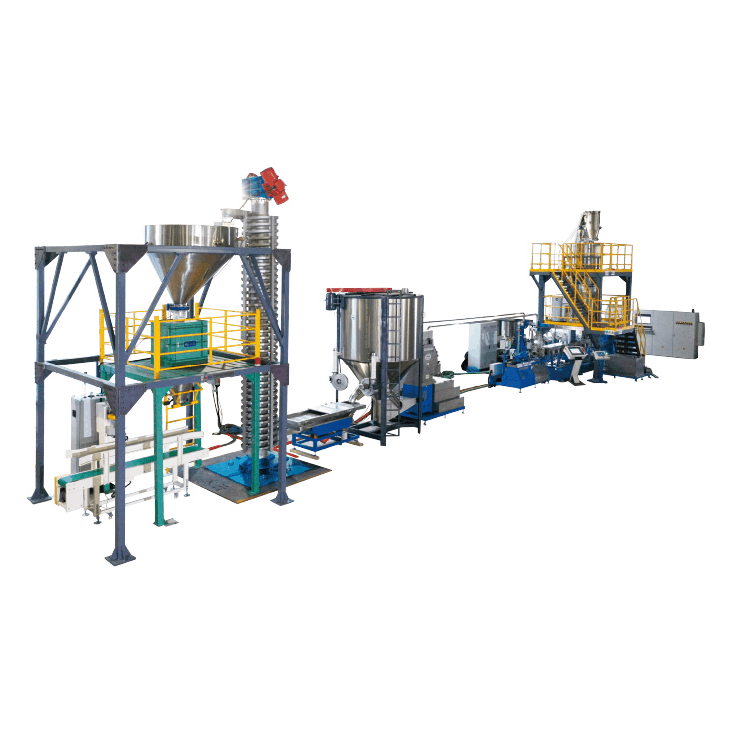

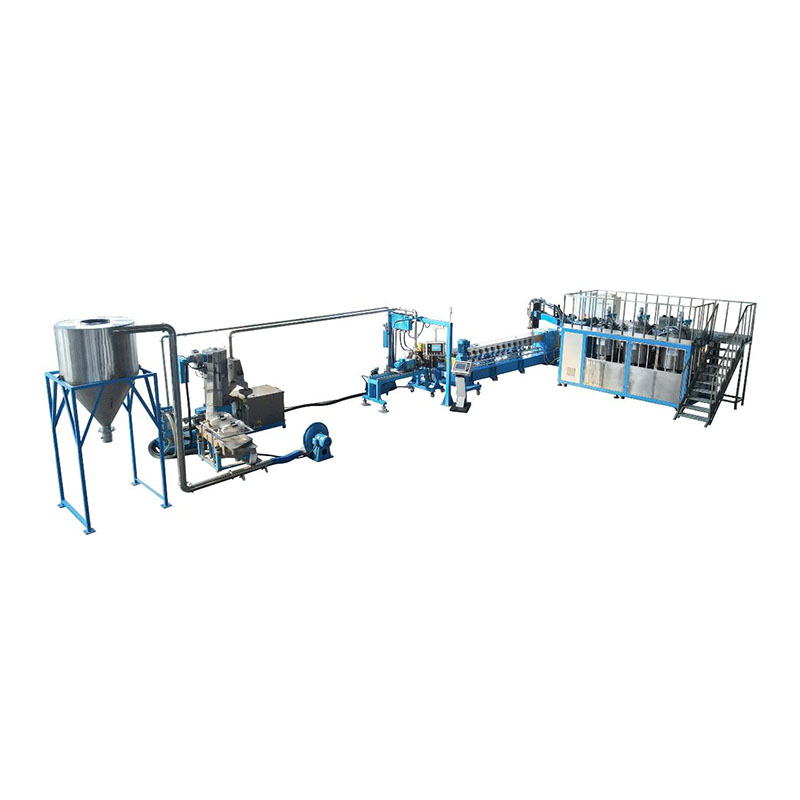

Single Screw Extruder Pelletizing Line Application

Single screw extruder pelletizing line

Video

How To Properly Operate The Pelletizing Machine

Pelletizing machine is a necessary equipment for many waste plastic enterprises.

Proper operation and use of the pelletizing machine can not only improve production efficiency, but also extend equipment life, reduce production costs, and improve product competitiveness. Therefore, we must properly operate, reasonably apply and properly maintain the pelletizing machine to ensure the normal operation of the pelletizing machine.

Pelletizing machine operation

The operation of the pelletizing machine includes a series of links including the device installation, adjustment, commissioning, operation, maintenance and repair.

When using the pelletizing machine, special attention should be paid to its characteristics, and the operating points of the pelletizing machine should be well grasped.

Although the operating points of various pelletizing machines are different, they also have similarities.

1. Preparation before starting pelletizing machine

If the recycled material is used as the raw material for extrusion molding, the raw material should meet the required drying requirements, if necessary, further drying is required, and the recycled material is sieved to remove agglomerates and mechanical impurities.

Before operating the pelletizing machine, you need to check whether the water, electricity and gas systems in the equipment are normal to ensure that the water and gas channels are smooth and leak-free.Check whether the electrical system is normal, check whether the heating system, temperature control, and various instruments work reliably;Test run the auxiliary machine at low speed and observe whether the equipment works normally;Start the setting table vacuum pump and observe whether the work is normal;Lubricate the smooth parts of various equipment. Remove the fault if found.

According to the product variety and size, choose the specifications of the machine head and install them; clean the perforated plate and the various parts of the machine head, and replace the filter screen.

2. Start up pelletizing machine

Pelletizing machine can be started after constant temperature,Tighten the bolts of the machine head and the pelletizer flange again before turning on the machine to eliminate the difference in thermal expansion between the bolt and the machine head. The order of tightening the machine head bolts is diagonally tightening with even force.When tightening the flange nut of the machine head, it is required to be uniformly tight all around, otherwise the material will run away.

When operating the pelletizing machine, first press the “ready to start” button, then press the “start” button, and then slowly turn the screw speed adjustment knob to start the screw speed slowly.Then gradually speed up, while adding a small amount of raw materials.When adding raw materials, pay close attention to the indication of the host ammeter and various indication meters.Screw torque must not exceed the red mark.When the pelletizing machine is in operation, no one should stand directly in front of the die before the plastic profile is extruded to prevent injury accidents due to broken bolts or wet raw materials.

After the plastic is extruded from the die, according to the indication value of the control instrument and the requirements for the extruded product, adjust each part accordingly to make the entire extrusion operation reach a normal state, and add more raw materials as needed.

According to the condition of the extruded material, judge the plasticization degree of the material. If the plasticization is not good, the screw speed, barrel and head temperature can be adjusted appropriately until the requirements are reached.

Should regularly check whether the various process parameters are normal according to the process requirements, and fill in the process record sheet. Check the quality of the product according to the quality inspection specifications, and take corrective measures when problems are found.

3. Work after turning off the pelletizing machine

pelletizing machine operation stops feeding and squeezes out the plastic in the pelletizing machine. Turn off the barrel and head power and stop heating.

Turn off the power of the pelletizing machine and auxiliary machine to stop the screw and auxiliary machine.

If the machine head needs to be removed, cleaning work is required.Clean the perforated plate and the various parts of the machine head. When cleaning, prevent the internal surface of the machine head from being damaged.The remaining material in the machine head should be cleaned with copper sheets, and then the plastic adhered to the machine head is polished with sandpaper, polished, and coated with engine oil or silicone oil to prevent rust.

Cleaning of screw and barrel.Restart the main machine and add shutdown material (or broken material) to clean the screw and barrel. At this time, the screw is selected at a low speed to reduce wear.After the stopped material is crushed into a powder and completely extruded, the remaining pellets and powder can be blown out repeatedly from the feeding port and the exhaust port by compressed air. After there is no residual material in the barrel, reduce the screw speed to zero, stop the pelletizer, and turn off the main power and cold water valves.

Matters needing attention in pelletizing machine operation

The correct operation of plastic machinery can be used to extend its life. However, the use of plastic machinery does not get enough attention in our daily life, and it will also cause some unnecessary problems. So we must pay attention when using plastic machinery. What about those problems?

1. Pay attention to fire safety. The fire extinguisher should be placed near the equipment using thermal oil.

2. When a malfunction or abnormal situation occurs, the relevant personnel must be reported and handled by professional maintenance personnel. If any abnormal phenomenon affecting safety occurs, immediately press the emergency stop switch.

3. Do not use low-quality return materials with metal impurities or sand. Metal objects that may fall may not be placed near the feed port to prevent aggravating the wear of the screw and barrel, or causing jams and damage.

4. Plastic machinery operation should use hydraulic oil with cleanliness, viscosity and other indicators that meet the requirements, and provide sufficient flow of cooling water to the oil cooler in accordance with regulations to prevent hydraulic components and pipelines from being blocked or leaked due to oil pollution or high temperature Damage such as oil.The extruder should be filled with lubricant that meets the requirements.

5. Plastic machinery must be operated in strict accordance with the requirements of operating regulations, and illegal operations must not be performed at non-operating stations. To ensure the reliability of the safety device, the safety protection measures of the machine must not be destroyed for the sake of efficiency.

6. When the plastic machine is operating, the material temperature does not reach the set temperature, and the screw is not allowed to start when the holding time is not enough.

7. Operated by operators who are familiar with the mechanical properties and operating procedures of plastic machinery.

Failure analysis of pelletizing machine

During the daily operation of the pelletizing machine, various failures occur in the pelletizing machine, which affects the normal production of plastic machinery. Below is an analysis of some common failures of the pelletizing machine.

| Fault conditions | Cause Analysis | Solution |

| Host current is unstable | 1. uneven feeding 2. The main motor bearing is damaged or poorly lubricated 3. A certain section of heater fails 4. Screw adjustment pad is wrong |

1. Check the feeder 2.Maintenance of main motor 3. Check whether each heater is normal 4. Check the adjustment pad |

| The main motor cannot start | 1. The startup sequence is wrong, whether the fuse is burnt out 2. Problem with main motor thread 3. The interlocking device related to the main motor works |

1. Check the boot sequence 2. Check the main motor circuit 3. Check if the lubricant pump starts 4. The inverter induction power is not discharged 5. Check if the emergency button is reset |

| The head discharge is not smooth or blocked | 1. A section of heater does not work 2. Operating temperature is set too low 3. There may be foreign objects that are not easily melted |

1.Check heater 2.Verify the set temperature of each section 3. Clean and inspect the extrusion system and the head |

| Main electric start current is too high | 1. Insufficient heating time 2. A certain section of heater does not work |

1. Extend the heating time 2. Check whether each section of heater is working normally |

| The main motor makes an abnormal sound | 1. The main motor bearing is damaged | 1. Replace the main motor bearing |

FAQ

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~